Norfund invests through funds to reach more companies and other business areas than we can on our own. The fund managers contribute to develop local, sustainable companies based on regional expertise, industry insight and efficiency initiatives.

One of the funds we invest through is Novastar, which has the Nairobi-based circular waste company Regen Organics in its portfolio.

Fund investments in Norfund

Norfund’s has three objectives when investing in funds:

- Gain access to markets and segments in need of investments outside Norfund’s expertise

- Reach businesses in challenging business environments outside of Norfund’s direct reach

- Contribute to develop local businesses and improve business practices by utilizing competence and resources of local fund managers

Our fund managers possess local knowledge, industry insight and capabilities to grow SMEs (Small and Medium Enterprises). Norfund therefore sees fund managers as a valuable way to access investment areas that otherwise would be difficult. They create value through active ownership and professional expertise and provide local knowledge to support the company’s development and growth.

Novastar

Novastar is one of the first and largest global venture capital investors in Africa. With offices in Lagos, London and Nairobi, Novastar partners with transformative businesses forging solutions to Africa’s biggest problems and creating lasting, inclusive value for the many, for people and planet.

Since 2014, Novastar has backed the bold entrepreneurs that provide essential goods, service and economic opportunity to everyday consumers and producers in the fast-growing, often informal African markets where they live, work and shop. Norfund has a long-standing relationship with Novastar and has participated in both their funds to date.

Novastar has established an exciting portfolio with companies such as BasiGo, which offers public transportation through cost-effective electric buses, and Ignita which helps farmers battle the effects of climate change by providing hyper-local and accurate weather forecasts to farmers in the most remote areas. You can read more about Novastar’s portfolio here.

Today, Novastar has an active portfolio of 24 companies across two funds. One of these companies is Regen Organics.

Regen Organics

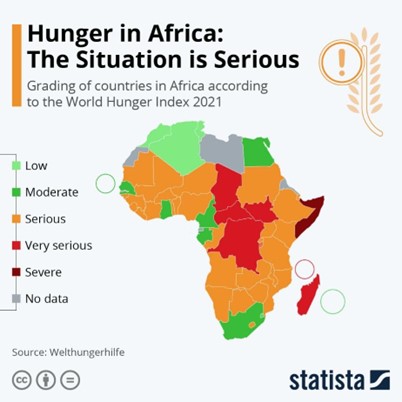

Two of the world’s most difficult challenges are food insecurity and safe waste management. These issues are particularly prominent in developing economies with 98% of the world’s undernourished living in developing countries and waste generation in the same economies expected to increase threefold by 2050.

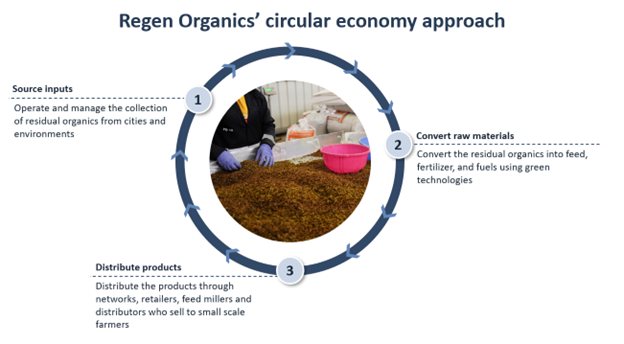

Regen Organics, a Nairobi-based company, aims to solve those problems. The company utilizes a circular economy approach to create organic fertilizers and animal feed inputs from organic waste, creating value from waste around Nairobi. The company has quickly become a leader in regenerative agriculture in Kenya and is aiming for expansion to other parts of East Africa.

Regen Organics’ fertilizers are made from locally sourced organic waste, such as food and sanitation waste, which is processed using a proprietary method to create high-quality organic fertilizers. These fertilizers are rich in nutrients, including nitrogen, phosphorus, and potassium, and are designed to enhance soil health and fertility, increase crop yields, and improve the quality of produce. Regen Organics’ approach to fertilizer production is sustainable and environmentally friendly. By utilizing a circular approach, the company is able to reduce waste and pollution while producing a valuable product for farmers.

The creation of the fertilizer involves several steps:

1. Collection: Organic waste materials such as food scraps, sanitation waste, and agricultural residue are collected from various sources. Regen Organics works with waste management companies, households, and farms to obtain these materials but operates the transportation of waste to the factory themselves. By sourcing waste from around Nairobi they are mitigating the amount of waste that ends up in nature while creating an ecosystem for waste management.

2. Sorting and preparation: The collected waste is sorted to remove any non-organic materials such as plastics and metals. The organic materials are then shredded and mixed to create a uniform feedstock for the next step.

3. Feeding the black soldier fly larvae: The mixed feedstock is fed to black soldier flies in a controlled environment. The larvae can consume large amounts of organic waste and feed for around 2 weeks before it reaches optimal size for harvesting.

4. Harvesting the larvae: Once the larvae have consumed the feedstock, they are harvested and processed to create a protein-rich additive for animal feed. The harvested larvae can be dried, ground, and mixed with other ingredients to create a balanced feed for animals such as poultry, fish, and pigs, replacing unsustainable protein sources like fishmeal and soya.

5. Composting: The residue from the larvae production is combined with carbon-rich organic waste streams and is further processed through a composting stage, where it is mixed with other organic materials and allowed to decompose under controlled conditions. The composting process produces a rich, nutrient-dense soil amendment that can be used as a fertilizer.

In addition to organic fertilizer, Regen Organics makes biomass briquettes that can be used for industrial purposes – including Regen’s own boilers – and replace fossil fuels.

Through their products Regen Organics is committed to supporting smallholder farmers in East Africa by providing them with access to high-quality, affordable organic fertilizers and animal feed, while also offering training and support to help them adopt sustainable agriculture practices and improve their yields and incomes.

Development effects

Through their circular economy approach Regen Organics has several positive impacts. By utilizing organic waste as an input, the company upcycles over 60,000 tons of residual organics annually, reducing waste and carbon emissions, and offsetting 50,000 tons of carbon. This approach promotes sustainable agriculture and addresses critical challenges such as waste management and climate change.

Secondly, Regen Organics’ fertilizers and animal feed are affordable options for small-scale farmers, making them accessible for most agricultural producers in Kenya. This accessibility helps improve soil fertility, crop yields, and animal health, contributing to poverty reduction and food security. Today more than 8,000 farms have adopted regenerative practices and benefit from this.

In addition, the successful establishment of the factory in Nairobi has created 500 direct jobs and 2,000 indirect jobs. With the newly raised capital Regen Organics will be able to scale up their production and by adding another factory the demand for workers will increase resulting in higher job creation.

Overall, Regen Organics’ circular economy approach has several positive development effects, including reduced waste and carbon emissions, improved access to affordable and sustainable agricultural inputs, capacity building for small-scale farmers, and recognition of innovative approaches to sustainable agriculture. These effects can contribute to a more resilient and equitable food system, promoting sustainable development in Kenya and beyond.

How capital from Novastar helps Regen Organics expand

Regen Organics’ fertilizer and animal feed has proven to be in high demand across Kenya and the company needs to scale up production to be able to meet that demand. With farmers experiencing an increase in yield of up to 30% in horticulture and prices for fertilizer increasing as a consequence of the war in Ukraine, Regen Organics has raised a new round of capital to expand its capacity as locally produced fertilizer is in high demand. This will be done through increasing capacity at the existing factory in Nairobi and building a second factory in western Kenya to be able to secure more organic waste and have better control on the value chain.

The process of handling the waste takes six months from when it arrives at the factory until it leaves as fertilizer, requiring substantial amounts of working capital to secure enough organic waste as input. Managing Director Michael Lwoyelo explains that the long-term goal is to expand the capacity to be able to process 1,500 tons of waste a day, five times higher capacity than today. With the expansion of a second factory the plan is to expand across Africa.

“Novastar are very active owners with their participation in the board, with strong ESG focus, and it’s a benefit for us that they have a long-term ownership horizon which in turn helps us grow at the right pace,” Michael added.